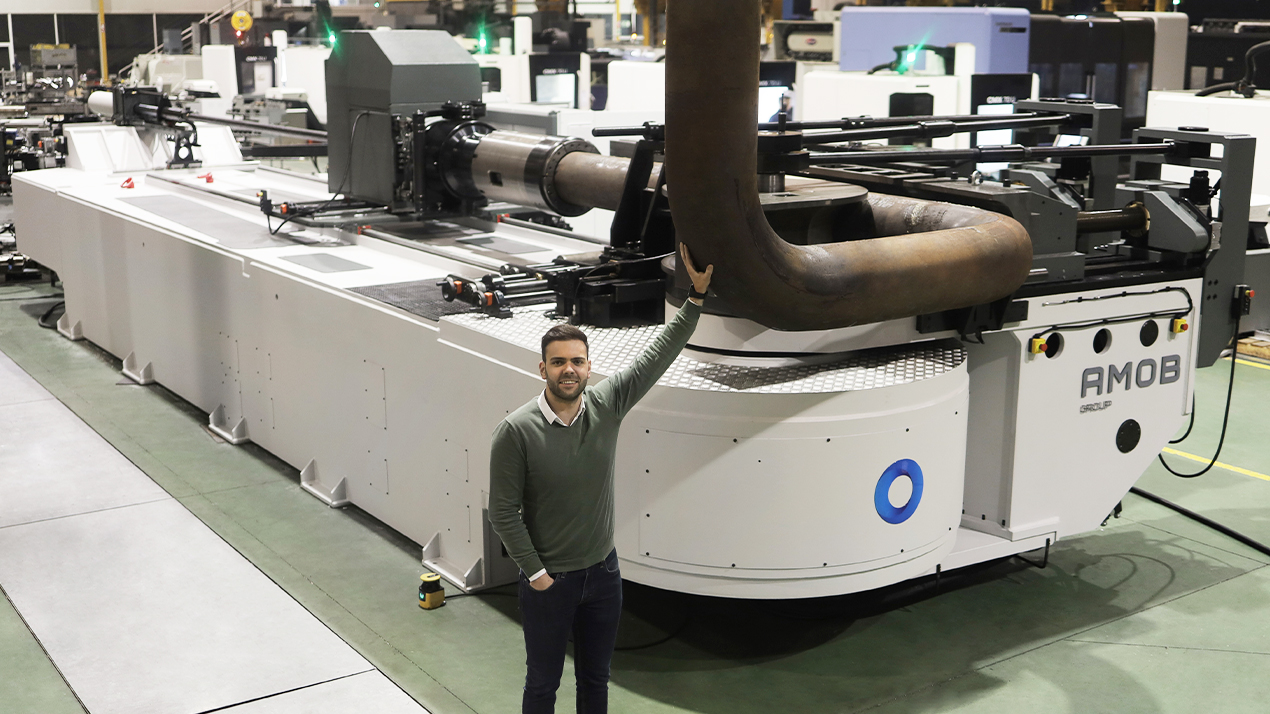

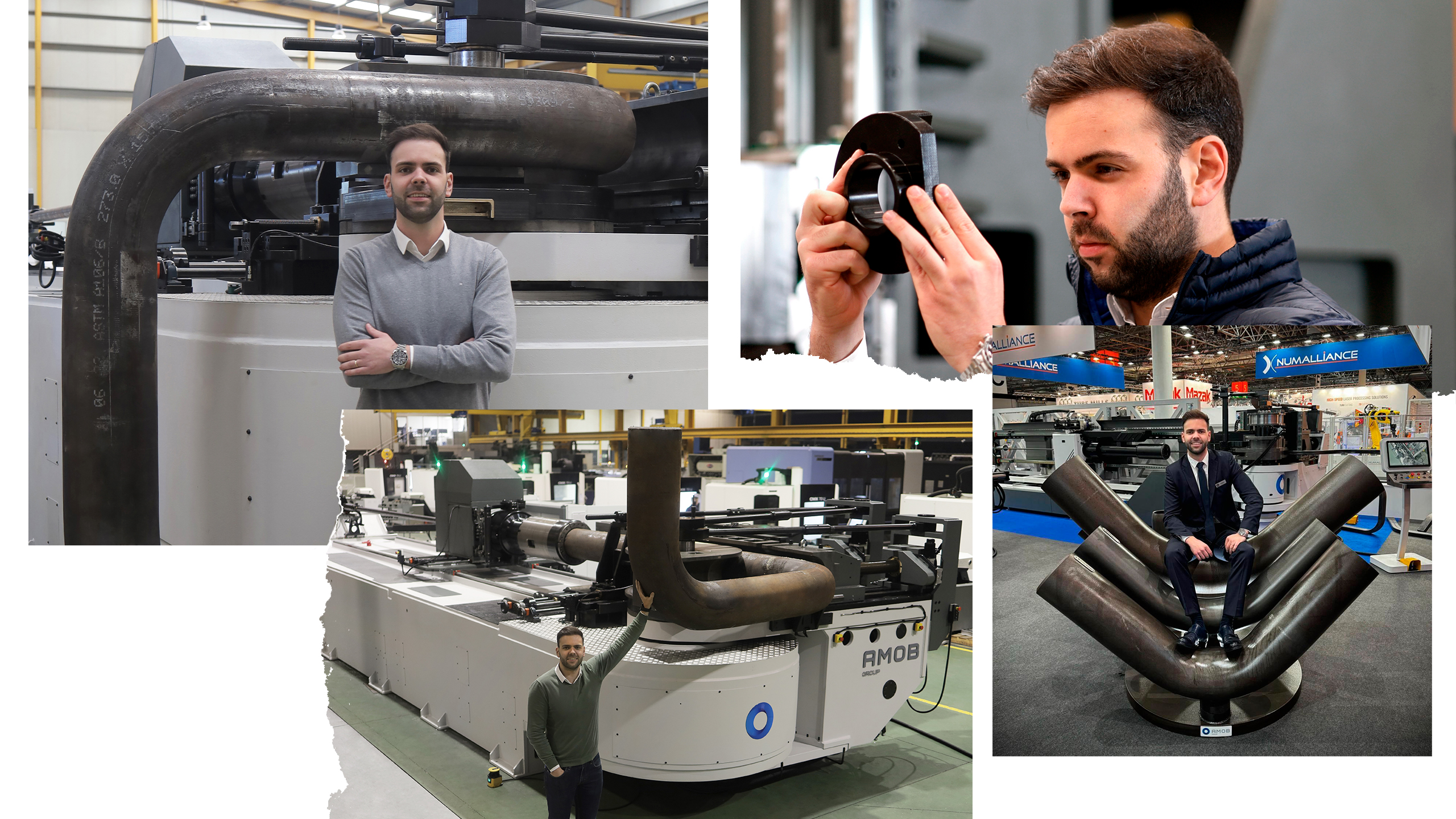

Manuel A. Barros - Interview

By Luisa Santos - InterMetal

With more than six decades of history, tube bending machine manufacturer, AMOB, has remained family-owned and is now experiencing a third generation of leadership. InterMetal spoke to Manuel António Barros, the founder’s grandson, who points out to the flexibility of family management and the versatility of the equipment as decisive factors in AMOB‘s success. Believer in the sector’s technical capacity which, as he says, is superior to “99% of the countries that have a metalworking industry”, he leaves a warning: without people there is no industry and Portugal has to step up its game if it wants to retain and attract qualified workers, who are so necessary in this sector.

Manuel has taken on a leading role at AMOB. Will your father hand over the baton to you soon?

This handover, as you say, is a natural process that will happen in two or three years’ time. I’ve always had a very strong connection to AMOB. Over the years, I’ve spent a lot of time at the company and have naturally become aware of the work carried out in all areas. Since the beginning of 2019, I’ve been here full-time and I follow the day-to-day life of all departments, across the board, from sales to production, including design. I’m, in fact, closely involved in the development of new products. AMOB‘s employees have played a key role in this process by passing on their knowledge of the various areas of the company to me.

Is this change in any way reflected in the way the company operates and how it presents itself to the market?

I would say that there are no changes in the way the company operates, but there are in the way it presents itself to the world, with more consistent, clear and assertive communication about our activity and what we have to offer to the market. Since my sister and I started taking on more responsibilities at AMOB, we have been concerned with making the brand better known and more appealing. We’ve rebranded the entire company image, including the logo and website, and we’ve put a lot of effort into external communication.

In fact, you’re clearly committed to a greater digital presence…

Today, digital presence is fundamental, mainly because it allows us to reach customers who are geographically more distant. This is without a doubt where we are investing the most, with the aim of showing the world who AMOB is and what solutions it offers. And the truth is that it’s already a winning bet.

Do you still intend to turn every customer into a friend, as your grandfather, António Barros, the company’s founder, used to say?

I do! First of all because customers are the ones who feed us, we depend on them to keep our doors open. But also because they give us something very valuable: feedback on the operation of the machines, which we need to improve our products.

Basically, if we have this good relationship, our customers can function almost as another element of our R&D department. This allows us to improve our product and allows the customer to have a better product. It’s definitely a win-win, mutually beneficial relationship.

Four years ago, AMOB had a turnover of 20 million euros, mostly in foreign markets. What is your current turnover and what percentage of it is exports?

If we only consider AMOB Portugal, we still have a turnover of around 20 million euros. But in the last four years, we have opened several subsidiaries in different parts of the world, which invoice directly. If we also considered their turnover, we would now be at 25 million euros, with a percentage of exports of around 90%. Of this percentage, 70% corresponds to intra-Community exports.

Which markets account for most of your business?

Fortunately, we operate in very diverse geographic markets. There is no market in the world that accounts for more than 10% of our turnover. In Europe, we have customers in practically every country, from Spain to Germany, UK and Italy, all with very balanced figures and very close to each other.

And what about the sectors?

Fortunately, tube bending machines are applicable to all kinds of sectors (from A to Z, as my father says). We sell machines both to people who make metal furniture and to people who make 300-meter-long ships. We have machines that bend 10 millimeter diameter tubes and machines that bend tubes the size of the machines that bend 10 millimeter tubes. So, in this respect too, we do not have a dominant customer sector that accounts for more than 15-20% of our turnover.

We have seen some international competitors who are very dependent on the automotive sector, and now, with the transition to electric vehicles without exhaust pipes, they are finding it very difficult to enter other sectors because their equipment was developed for that specific area. As AMOB has never had a dominant sector, it has naturally developed very flexible equipment.

Precisely for this reason, if I had to single out one customer sector, I would say that it is service providers. These companies, which have customers in various areas, need versatile equipment that can be adapted to bend exhausts, structural tubes for gym machines, furniture, among many other applications.

But the automotive sector continues to be seen as a growing market in terms of tube consumption…

Yes, in electric vehicles there are still a lot of bent tubes, but for the most part we are talking about different applications. Of course, there are still bent tube applications in hydraulic transport systems for brakes, some chassis are still made with bent tubes and profiles, but one of the main applications, for exhaust systems – made up of parts with multiple bends, some of them quite complex – will disappear with electrification. On the other hand, there is a great demand for smaller pipes, used in battery cooling systems.

In any case, we believe that the future will not necessarily lie with electric cars, but with other technologies such as hydrogen and green hydrogen, which do not need batteries. In any case, machine manufacturers will have to adapt to this new reality.

Generally speaking, what is your opinion of last year?

It was a year in which we once again broke financial turnover and productivity records, which we are pleased with. I also believe it was the last year in which we still experienced some difficulties due to the pandemic.

What are your predictions for this year?

Our prospects for 2024 are good. As I said, this will be the first ‘clean’ year, in which the effects of the pandemic on business will no longer be felt. I’m pleased that we’ve turned the page and that we can face the coming years, certainly with new challenges, but without that burden. It’s true that this year is getting off to a slightly atypical start, but I think it’s only a matter of time before companies regain the necessary confidence.

Even so, at the beginning of January we already had an order book that allows us to satisfy more than half of the year’s orders, we have a very complete sales funnel and so we have the prospect of closing the year, in terms of production capabilities, during the second quarter.

Were new models launched in 2023? Are new launches planned this year?

We launch new models every year. And I’m not talking about adaptations made to old machines, but really new equipment. We think it is essential to constantly keep up with the evolution of the industries and sectors we work for, and that means constantly launching new solutions.

We have some competitors who are more resistant in this respect and it is precisely these who are experiencing some difficulties, for example, with this transition in the automotive sector. To give you an example, some still insist on using machines designed for exhaust pipes in air conditioning applications, which doesn’t make much sense.

At AMOB, thanks very much to the family management of the company, we have the necessary flexibility to make the decision to launch new models quickly and without bureaucracy.

Would you say that family management is one of the factors contributing to AMOB’s success?

Without a doubt. Even though AMOB has an increasingly professional structure, it is still a family business, which, in my opinion, has the great advantage of allowing us to make decisions more easily, based not necessarily just on numbers, but also on instinct, and this speeds up the development process a lot. When someone brings us an idea that fits our vision, we are the first to want to test it out, and as quickly as possible.

Which of the innovative technologies that make up your machines would you like to highlight?

My main highlight is the progress we have made in the software that controls our machines. As with the entire manufacturing process, we are also completely vertical with our software. All the software is developed in-house by a department that is now 300% larger than it was five years ago, when I joined the company full-time. And our goal is for it to continue to grow. Thanks to this commitment, we now have a software that is faster, more intuitive, more capable, and which offers more solutions to our customers.

Is the energy efficiency of equipment a concern for AMOB?

Absolutely. We are attentive to world trends and one of today’s keywords is efficiency, energy efficiency and not only. At AMOB we have put a lot of effort in this direction. For example, our software has been designed to make our equipment energy efficient, allowing machines to remain in sleep mode when not in use. In addition, key components such as motors and drives are getting increasingly efficient in our machines.

What other measures are part of your sustainability policy?

We are investing so that, by 2025, more than half of the energy we use will come from renewable sources and, to this end, we will soon be installing a large network of photovoltaic panels. In addition, in production, we are concerned with replacing older, inefficient equipment with newer equipment that will give us the same advantage that we are offering our customers.

Does AMOB recondition used machines?

Yes, but we are very aware that sometimes it is difficult to recondition a very old machine with 100% up-to-date technology. On those more extreme cases, we give our customer a strong incentive to scrap the old equipment and buy a new machine. In these cases, we dismantle and recycle 80 to 90% of the components of the old machine – our machines are almost entirely made of metal and a positive aspect of this material is that it is 100% recyclable.

With regard to your manufacturing process, have you invested or are you planning to invest in digital transformation or process automation tools?

Always. In fact, my dream is, in the future, to have part of the factory working while we all sleep. And, at the same time, to have digital transformation tools that allow us to understand if the factory is working well, if it is being efficient, how much it is producing. In this sense, we have been investing a lot in tools such as the software we installed a while ago to control the productivity of all our equipment, and also in process automation, with solutions that allow us to keep the machines running without an operator. These two aspects, digital transformation and automation, are fundamental if we are to continue to grow (and be competitive) and they are in fact interlinked: it does not do us any good just to have automated processes if we can’t measure them. These are areas in which we will certainly continue to invest.

In the midst of all the technology available, the human factor continues to play a central role in the industry, with many companies reporting a lack of skilled labor. Does that also applies to you?

Yes, people are the central factor in any company, no matter how automated and digitalized it is. The tendency is to let machines do the most repetitive processes, in order to free up people for more interesting tasks that require some cognition and have greater added value.

The shortage of staff is a problem that affects our sector a lot, and AMOB also suffers from it, hence this being one of the reasons we’ve invested so much in automation. Fortunately, this shortage has been countered by some highly qualified immigration that has come to us, mainly from countries like Brazil, India and Pakistan. I can tell you that we currently have ten Brazilian technicians working at AMOB, all of them very well prepared and performing specialized tasks.

If we want our companies to grow, we’re going to have to be able to attract this qualified labour. To this purpose, Portugal has to make itself attractive, both in terms of taxes and the living conditions it offers to people.

Besides this, what other challenges will the Portuguese metalworking industry have to face in the coming years?

I think the workforce is the main challenge. If we have competent, capable, motivated and happy people, we can easily face any challenge. However, people need to be able to be paid well and not have half their income taken up by taxes. It would be important for them to be able to take more money home, and I think we’re going to struggle to find qualified workers otherwise. We must not forget that we are competing with countries where salaries are much higher and which also have the same shortage of people.

Finally, how do you see the future of this industry?

I see a very bright future… if we manage to retain talent in Portugal. I think the Portuguese metalworking industry is very resilient. I have no doubt that we are technically better than 99% of the countries that have a metalworking industry. Yet we need to give people the conditions they need to lead decent lives. We have to create those conditions. If we do that, we have all the ingredients we need to grow.