The New Tube Bending Machine - CH 350 by AMOB

CH 350

The new CH 350 CNC is equipped with state-of-the-art features, including intuitive control interfaces, precision sensors, and safety features. This innovation allows operators to program and monitor each step of the bending process in real time, resulting in greater flexibility and a reduced margin for error, while minimizing material waste.

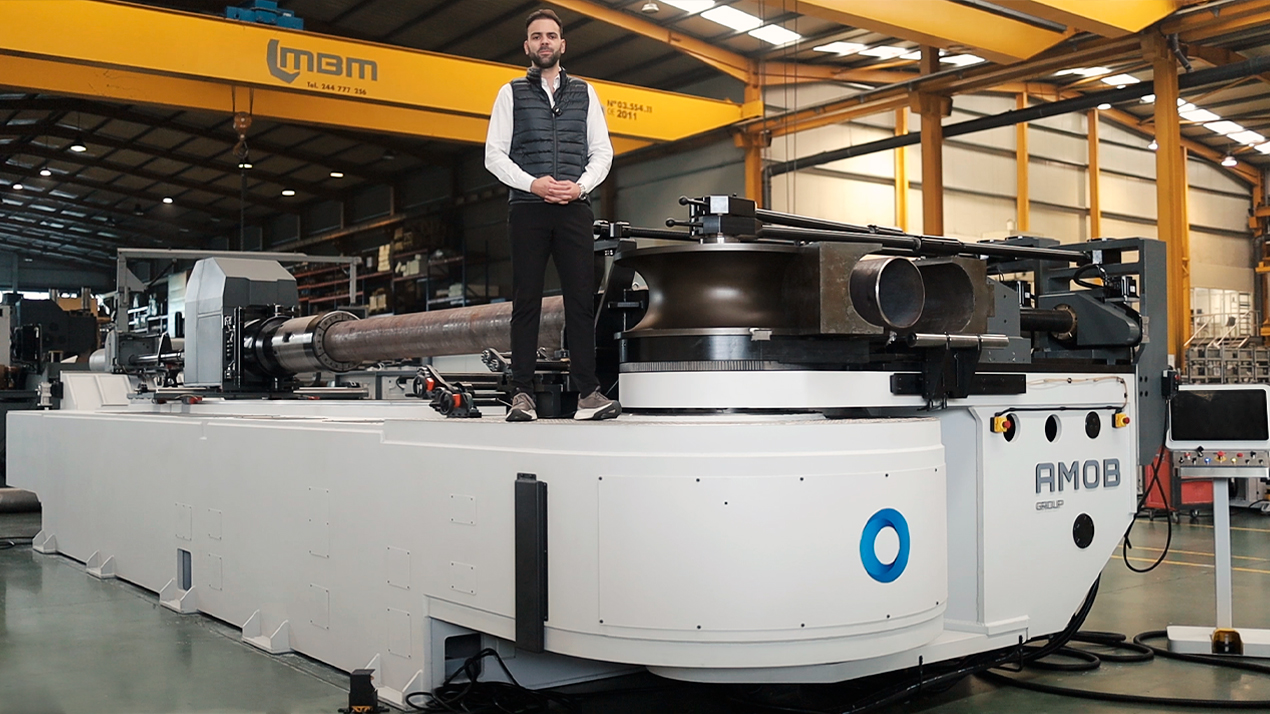

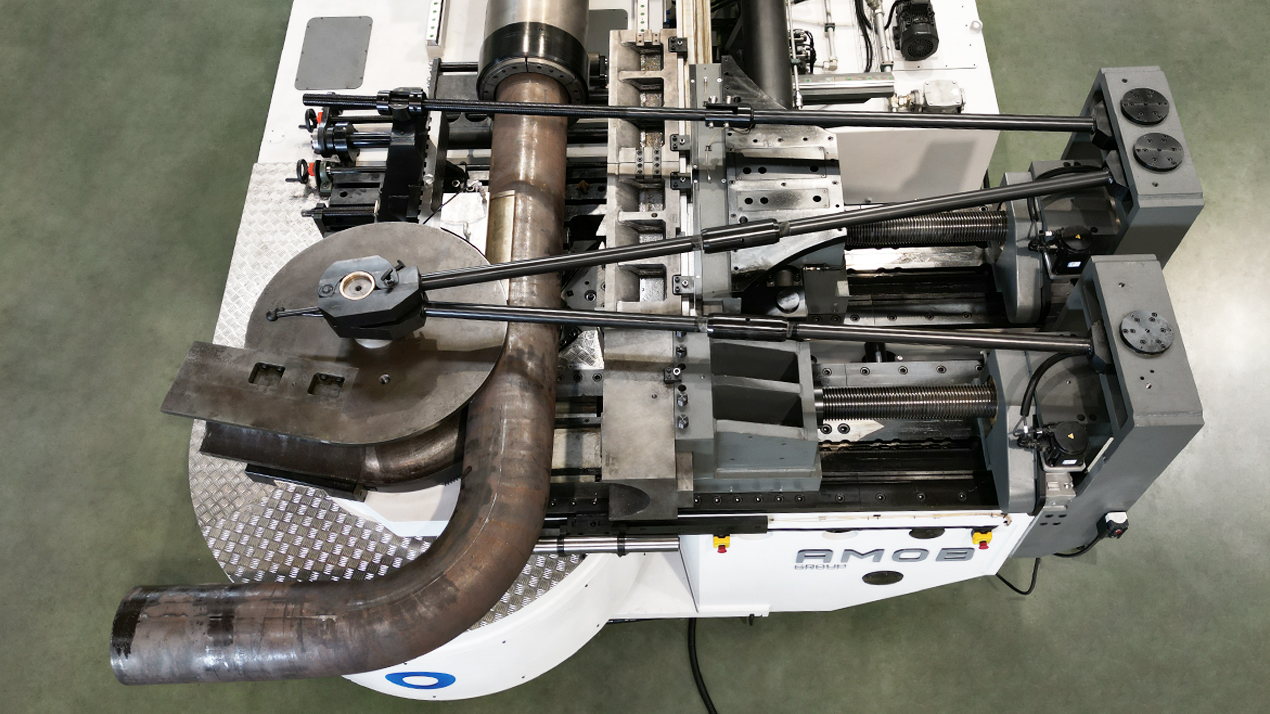

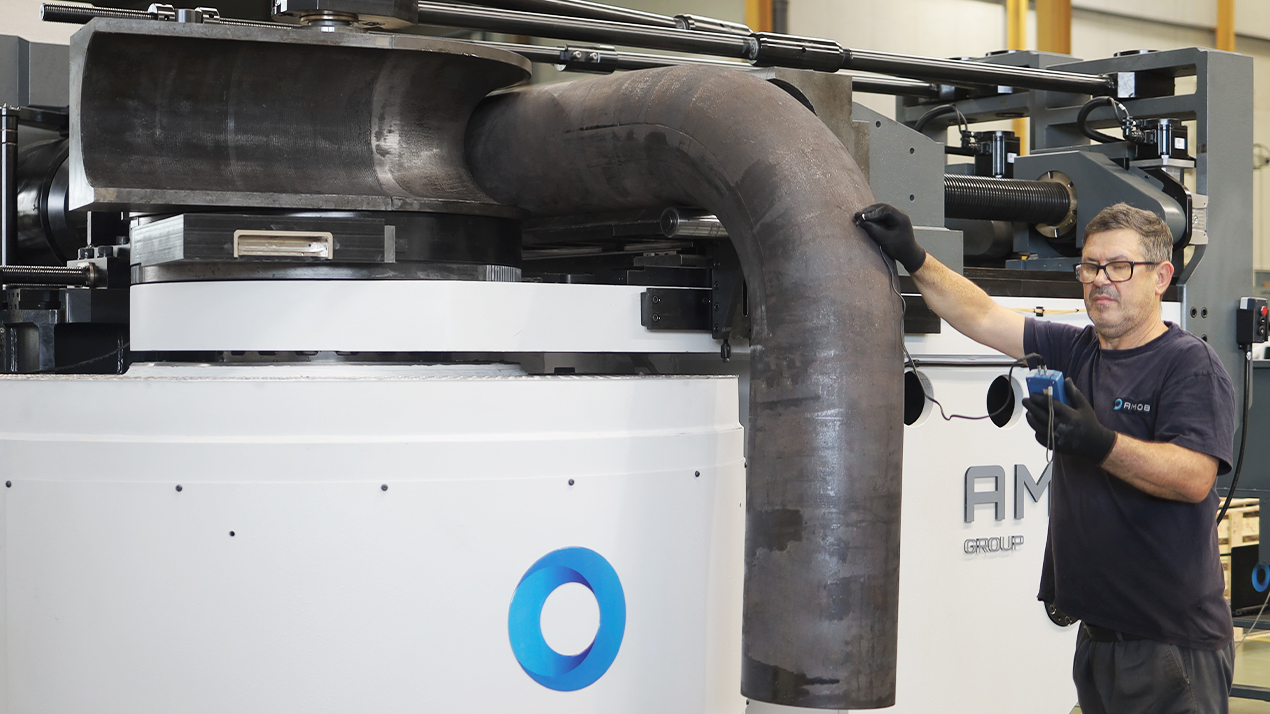

Optimised for tubes from Ø114.3 millimetres up to Ø355 millimetres, the CH 350 CNC can process bending radii up to 1000 millimetres. The carriage positioner is designed to handle tubes and profiles weighting hundreds of kg while maintaining the same levels of precision as smaller machines.

One of the challenges with a large machine, like the CH 350 CNC, is to load and unload the big and heavy tubes. Thanks to AMOB‘s latest CNC control, this process becomes simpler, easier, and safer. Another significant challenge with a machine of this size, some argue, is the tooling change over. Not in our CH 350 CNC where fully electric axes controlled by servo motors ensure the perfect positioning each time we change clamp and pressure die.

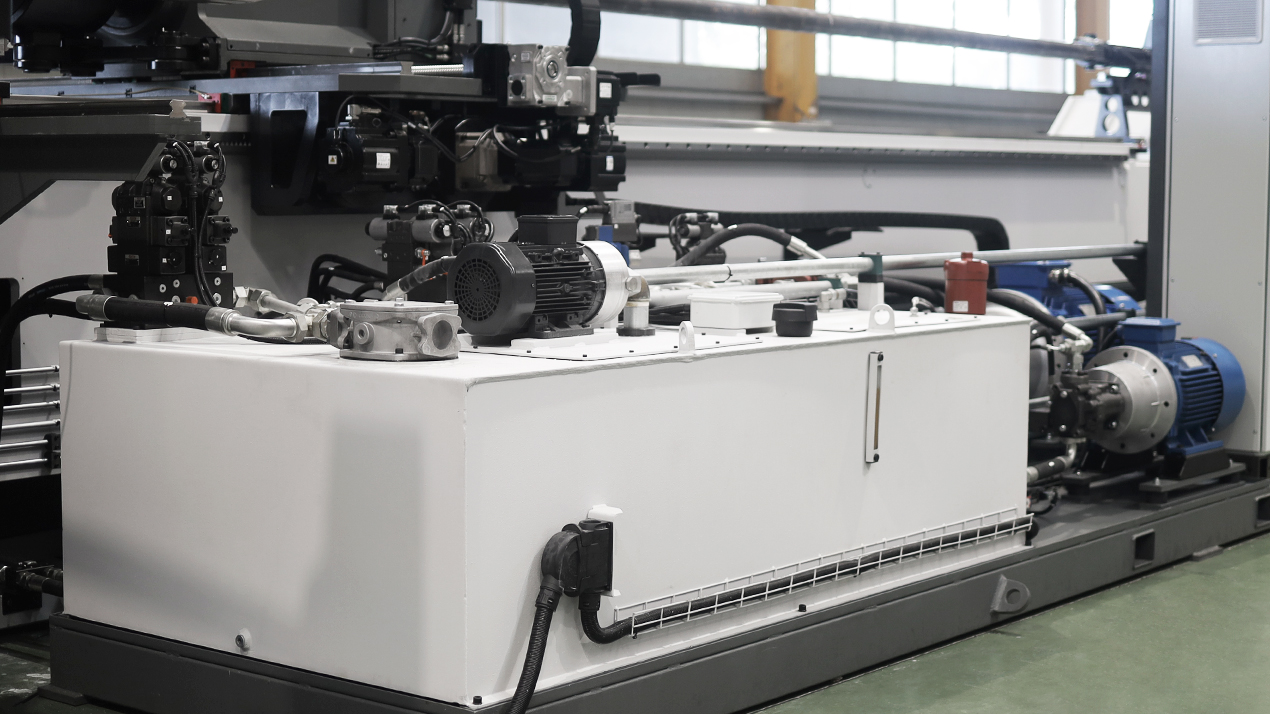

With a high installed power capacity, energy savings were always top of mind for the engineers behind this project. A carefully designed hydraulic system allows the CH 350 CNC to operate at lower energy costs compared to any equivalent competitor’s machinery.

Maintenance operations are quick and easy, as everything on the CH 350 CNC is easily accessible—from the main hydraulic controls to the centralized lubrication system and even the bending chain lubrication system.

The CH 350 CNC is built to be both rigid and robust, allowing even gigantic pipes to be bent with a centre line radius of just 1.5 times OD while maintaining minimum wall thining and ovalization.

With the launch of this new machine, AMOB strengthens its market leadership and offers customers a solution tailored to the demands of Industry 4.0, where automation and connectivity are essential to remain competitive. AMOB thus reaffirms its commitment to innovation and quality, characteristics that cement the brand as a global reference in bending solutions.