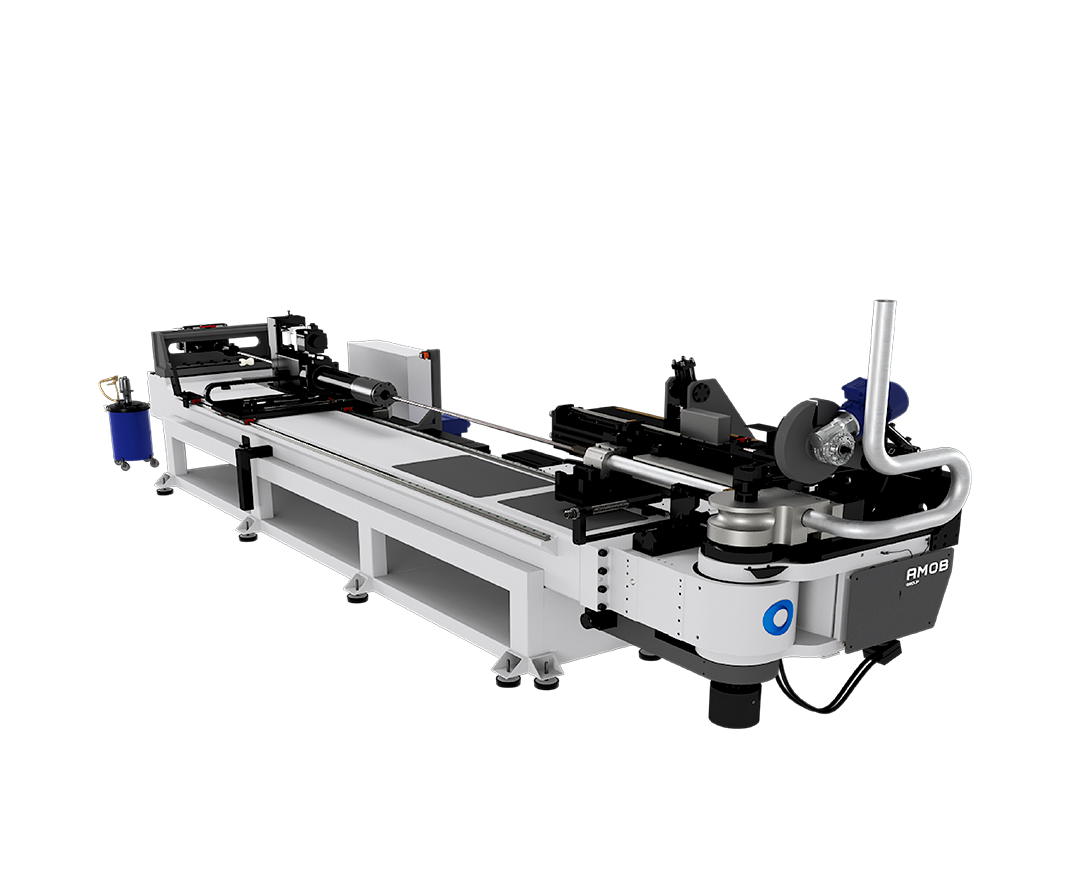

Hydraulic Tube Bending Machines -

CH Booster Series

HYDRAULIC TUBE BENDING MACHINES

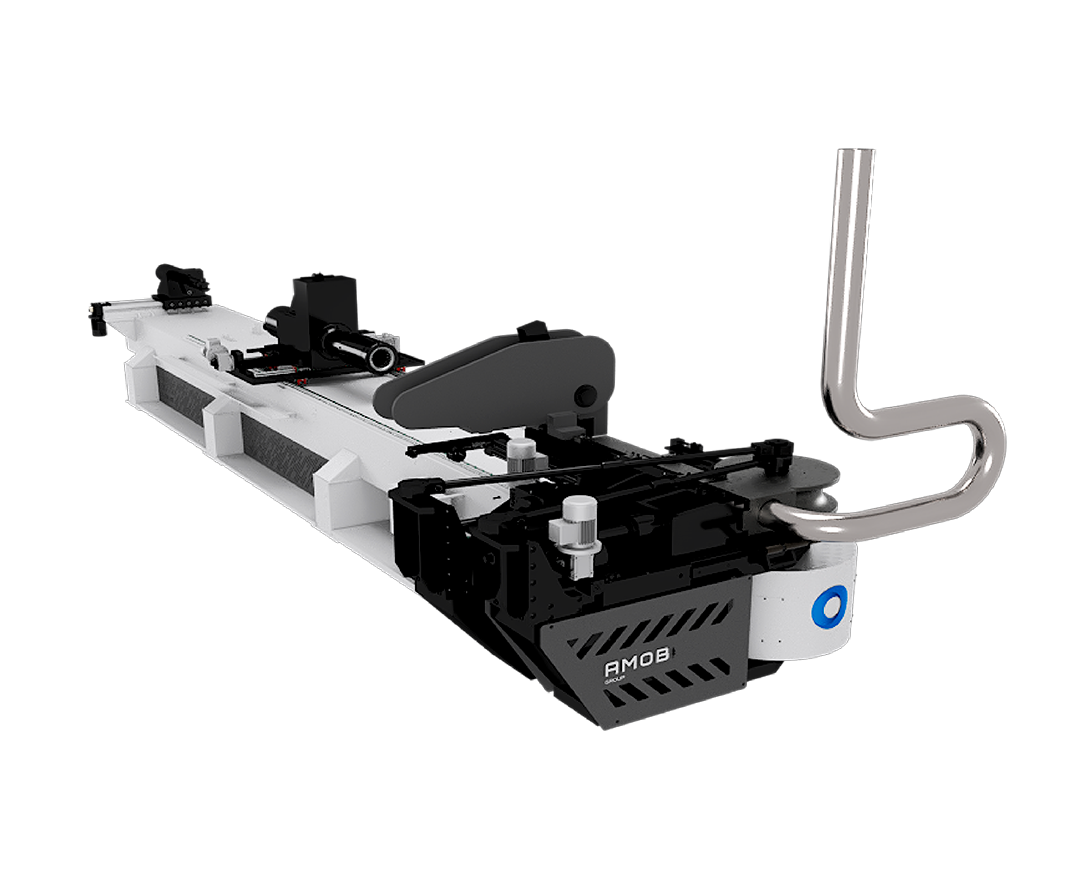

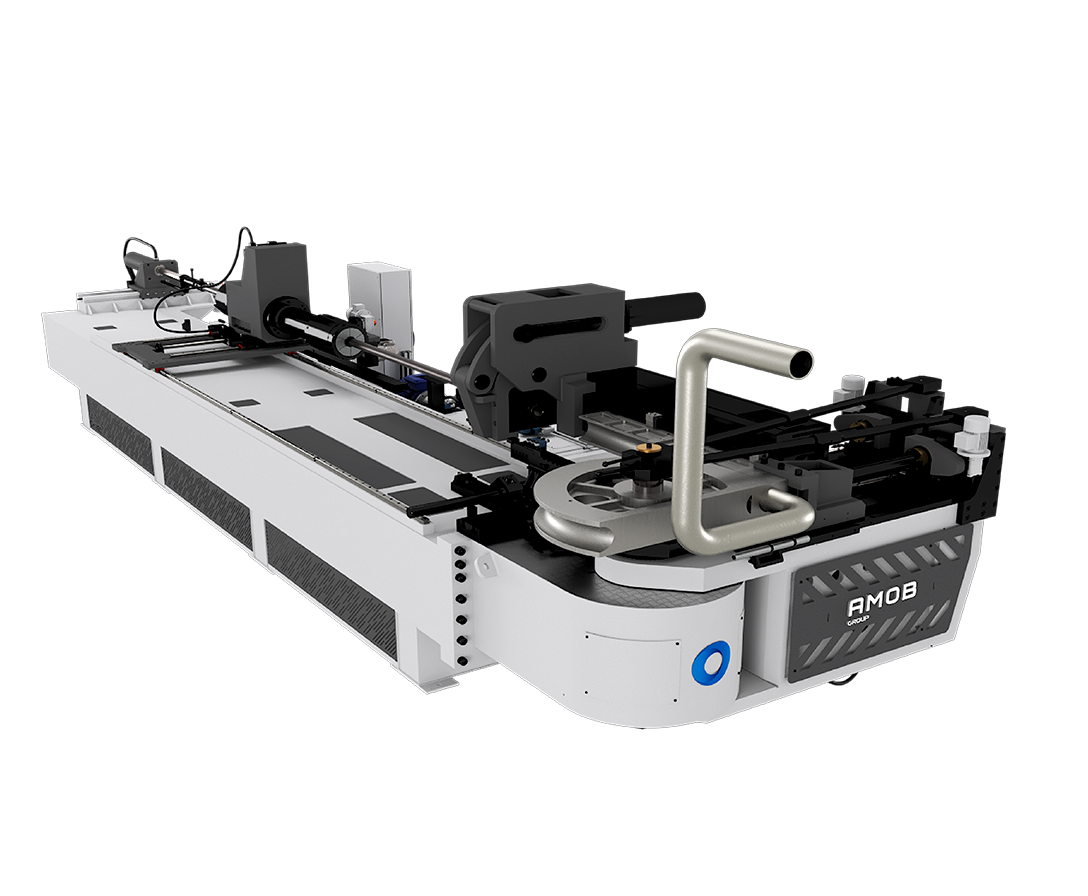

The booster mechanism is integrated into the follower pressure die – parallel to the centerline of the tube. To ensure proper grip of the tube, a secondary clamp is used behind the pressure die assist. To control the booster effect during the bend, operator can dynamically manage its behavior throughout the bending process – from 0° to 192° – using the machine software interface.

By adding a split die system, a cutting system, and laser reference system to a CH Booster, our customer can maximize the machine’s full potential, minimising auxiliary production processes like welding, cutting, inspection and more.

Combining the booster system with specifically designed tools, we manage to achieve low ovality and reduced loss of wall thickness even when bending mandrelless on >0,8D CLR/OD ratios.

OPTIONAL EQUIPMENT

FEATURES TO TAKE YOU TO THE NEXT LEVEL

Larger and more robust machines with undeniable precision, capable of producing the most rigorous tubes.

Programmable pump to keep mandrel lubricated during the entire bending process.

Die System

Allows single stack CH Series machines to produce bend-on-bend parts.

All machine activity is constantly monitored by an electronic motion control system, which provides information on the state of the machine, instructions, and any warning messages.