Sigma expands production capacity with the acquisition of a 100% electric tube bending machine – the eMOB 150 from AMOB

Sigma

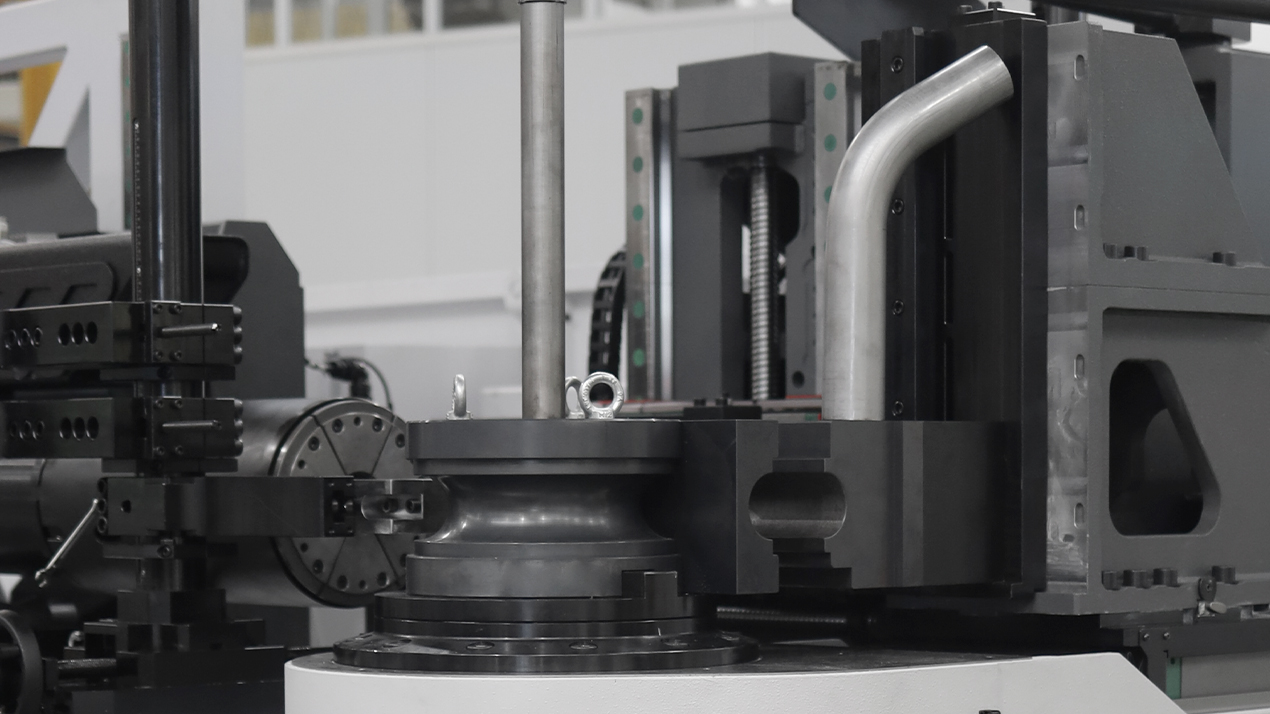

With cutting-edge technology, the eMOB 150 enables the execution of complex bends with maximum repeatability and quality. Additionally, its electric operation reduces energy consumption and eliminates the need for hydraulic systems, making the process more sustainable.

One of the highlights of the new eMOB 150 machine is its ability to produce tubes with a ratio between center line radius and tube diameter of 1D for Ø75×1.2mm tubes in Inconel Alloy 625, a highly resistant nickel alloy used in demanding applications, such as the aerospace industry. These electric machines can bend fixed and variable radii within the same cycle, handle special sections, feature multi-stack capability with up to eight tools simultaneously and produce parts with bends that have no straight lengths between them. The result is high-quality bends with minimal ovalization, even at lower center line radius-to-diameter ratios.

The carriage booster positioner and the high structural rigidity of the bending head allow bends with a CLR (centerline radius) < 1D (tube diameter) and helps to reduce the marks caused by the clamp die. Fully electric tube benders are the most energy efficient machines on the market. Their servo electric motors have the highest rate of energy efficiency and only use power when needed, with immediate response.

Sigma is a leading manufacturer of aerospace pipe and tube assemblies, ducts, manifolds, structures, sheet metal components, machined parts and specialized fasteners. This acquisition is part of Sigma’s strategy to continuously invest in cutting-edge technology to optimize its production line, reduce waste and expand its operational capacity.

This company works closely with its customers to maintain a set of approvals for various applications in aircraft components, propulsion systems and other systems. They provide and maintain reliable products and services that meet the high-quality standards set by each customer, including: Airbus, BAE Systems, Rolls-Royce, Siemens Energy, Boeing and Kawasaki.

According to Sigma, this new eMOB 150 machine will enable the company to meet the industry’s needs with even greater agility and precision, further reinforcing its commitment to innovation and excellence. With this acquisition, Sigma strengthens its competitive position in the market, offering advanced technological solutions and ensuring customer satisfaction.