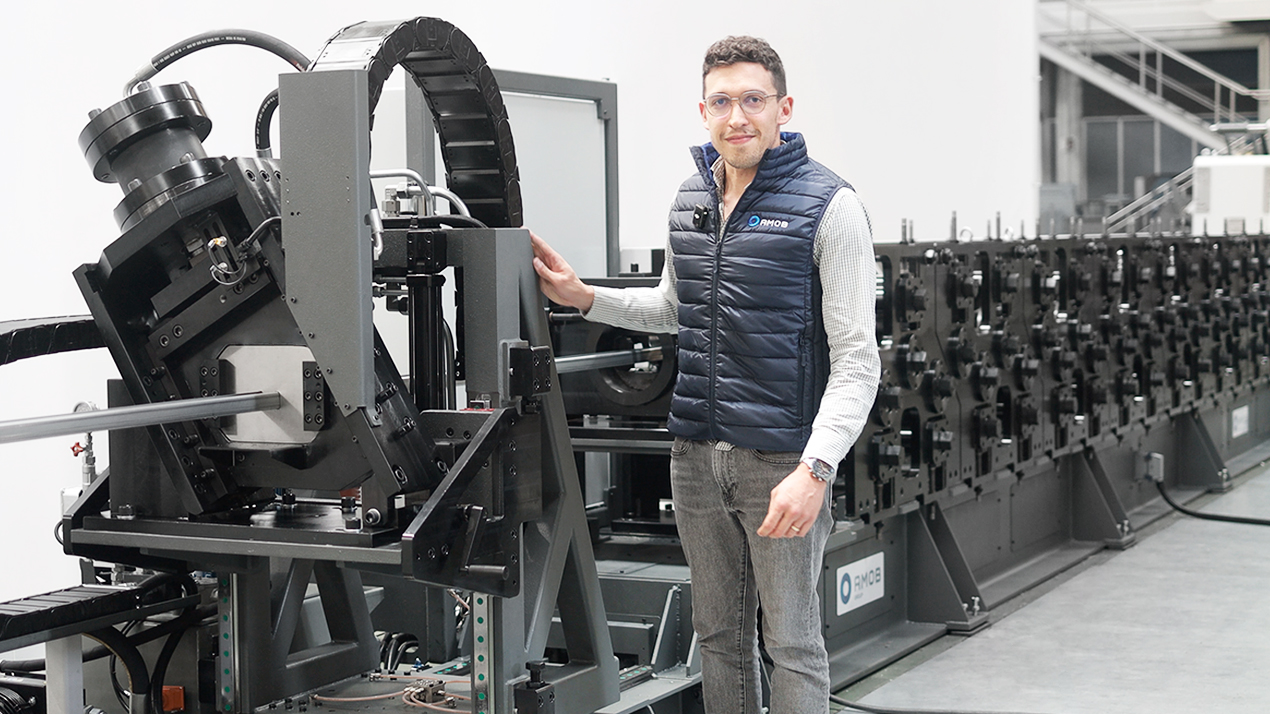

Roll Forming Lines – PF Series

STAND-ALONE ROLL FORMING LINES

With the possibility of processing sheet metal with thicknesses from 0.5 mm to 5 mm and widths up to 1500mm, AMOB roll forming machines are very comprehensive and capable of processing various types of materials such as aluminum, iron, lacquered and galvanized sheet metal, or sheet metal with any other type of surface finish.

The total production autonomy of AMOB group provides added flexibility when it comes to customizing products for our partners. Starting from sheet metal coils, it is possible to integrate various working processes, such as roll forming, cutting, punching, palletizing, packaging and even bending.

OPTIONAL EQUIPMENT

FEATURES TO TAKE YOU TO THE NEXT LEVEL

Synchronized and automatic operation of the entire rolling line, with programming through the CNC controller.

More automations, new functionalities and a unique combination between productivity and mechanisms based on Industry 4.0.

AMOB roll forming lines operate in sectors such as: Energy, Agricultural Industry, Construction, Structure Manufacturing, Furniture and Storage Systems.

Depending on the customer’s needs and the profiles to be produced, the roll formers are equipped with quick cassette change, adjustable tools for the production of profiles with different dimensions, multiple profiles on the same equipment, double roll forming with shared motorization, etc.