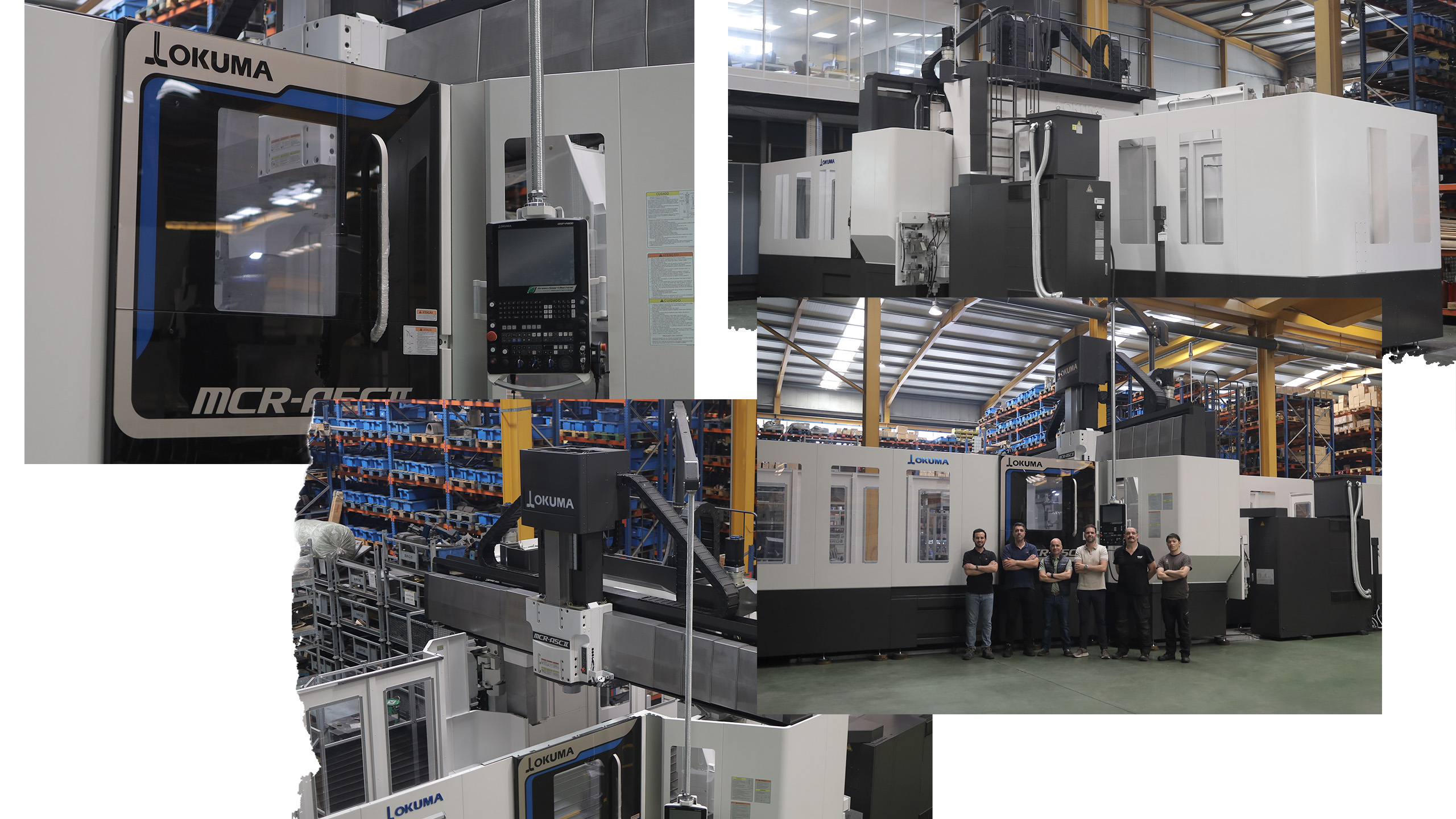

AMOB strengthens its production capacity with new Okuma MCR‑A5CII machining centre

Okuma MCR‑A5CII

Key features of Okuma MCR‑A5CII

Rigid gantry structure, ensuring stability and high dimensional precision, even under the most demanding operations;

Ram-type spindle head, ideal for deep cuts with robustness and control;

Thermo‑Friendly Concept technology, which automatically compensates for thermal variations, maintaining accuracy over time;

ATC (Automatic Tool Changer) and AAC (Automatic Attachment Changer) systems, enabling continuous operations with minimal manual intervention;

OSP‑P500 CNC control, Okuma’s latest generation control system, with significant improvements over the previous model (OSP‑P300), delivering greater intelligence, speed and process integration.

5-sided machining: a new paradigm for AMOB

The integration of the Okuma MCR‑A5CII represents a true revolution in AMOB’s machining process, particularly in the production of large and complex components. The ability to machine 5 faces in a single setup brings concrete, measurable advantages to daily production:

1. Drastic reduction in the number of setups:

Large and complex parts such as bases, rotary tables, columns or heads can now be fully machined in a single positioning, with no need for disassembly or repeated repositioning. This results in shorter preparation times, elimination of cumulative errors between stages and improved dimensional consistency between faces.

2. Absolute precision between planes:

By machining all critical surfaces in a single setup, dimensional deviation between opposite planes is avoided which is a critical factor in achieving perfect alignment of structural subassemblies. In AMOB‘s case, this precision directly impacts the final performance of its machines.

3. Flexibility for one-off parts or small series:

AMOB’s wide range of models and customised solutions demands a versatile and adaptable machining approach. With ATC (Automatic Tool Changer) and AAC (Automatic Attachment Changer) systems, the new machine quickly adapts to different geometries, responding swiftly to each new project.

Practical advantages and direct impact on production

The new Okuma brings clear, measurable benefits:

Fewer setups: Reduction in preparation time per part;

Higher precision between faces: Eased fitting and final assembly of subassemblies;

Less rework: Reduced waste and need for adjustment;

Greater production capacity: Ability to take on more projects;

Improved final quality: More robust, reliable equipment with tighter tolerances.

Technology at the service of AMOB engineering

This acquisition reinforces AMOB‘s commitment to remaining at the forefront of industrial engineering, consolidating its position as one of the world’s leading manufacturers of tube bending solutions. The new machine not only enables the production of larger, more complex and more precise structures, but also contributes to shorter lead times and greater vertical integration of internal processes, strengthening quality control and industrial autonomy.

With the Okuma MCR‑A5CII, AMOB continues to innovate and invest in the future of engineering and industrial production, placing technology at the service of excellence.