First AMOB Machines for Damen Naval Underwent Successfully Through FAT

Damen Naval

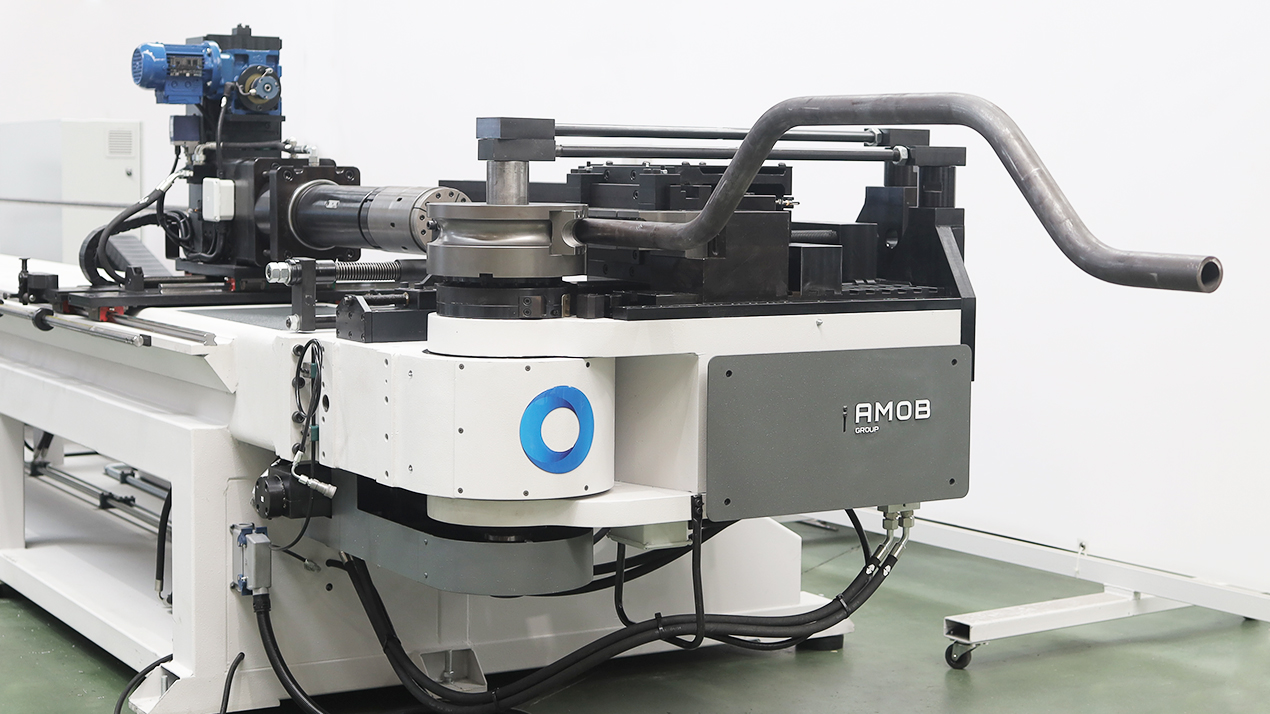

CH 80 stands out for its ability to perform complex bends in midsize diameters with speed and consistency, while CH 170 is designed for large-diameter tubes, ensuring the same quality and repeatability in more demanding applications. Both machines can work with materials such as Cunifer, stainless steel and carbon steel, covering a diameter range from 38 mm to 168.3 mm. These features make them ideal for meeting the requirements of the naval industry, where reliability and precision are essential.

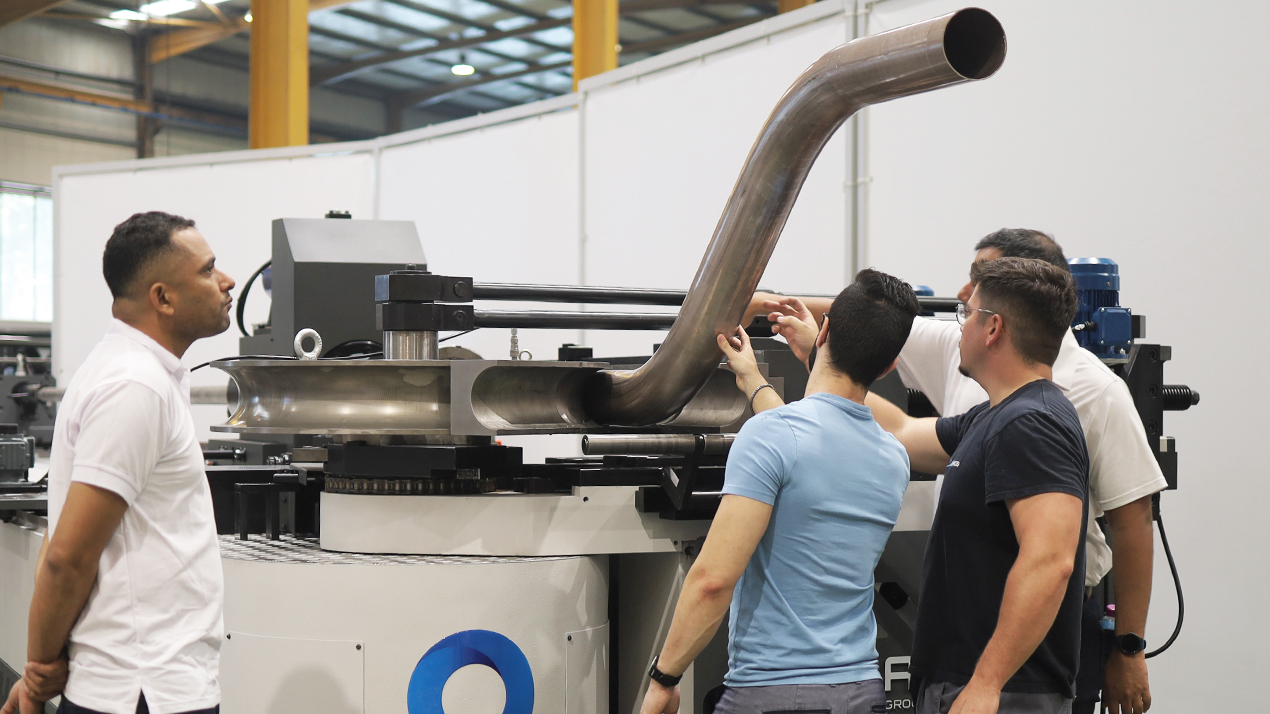

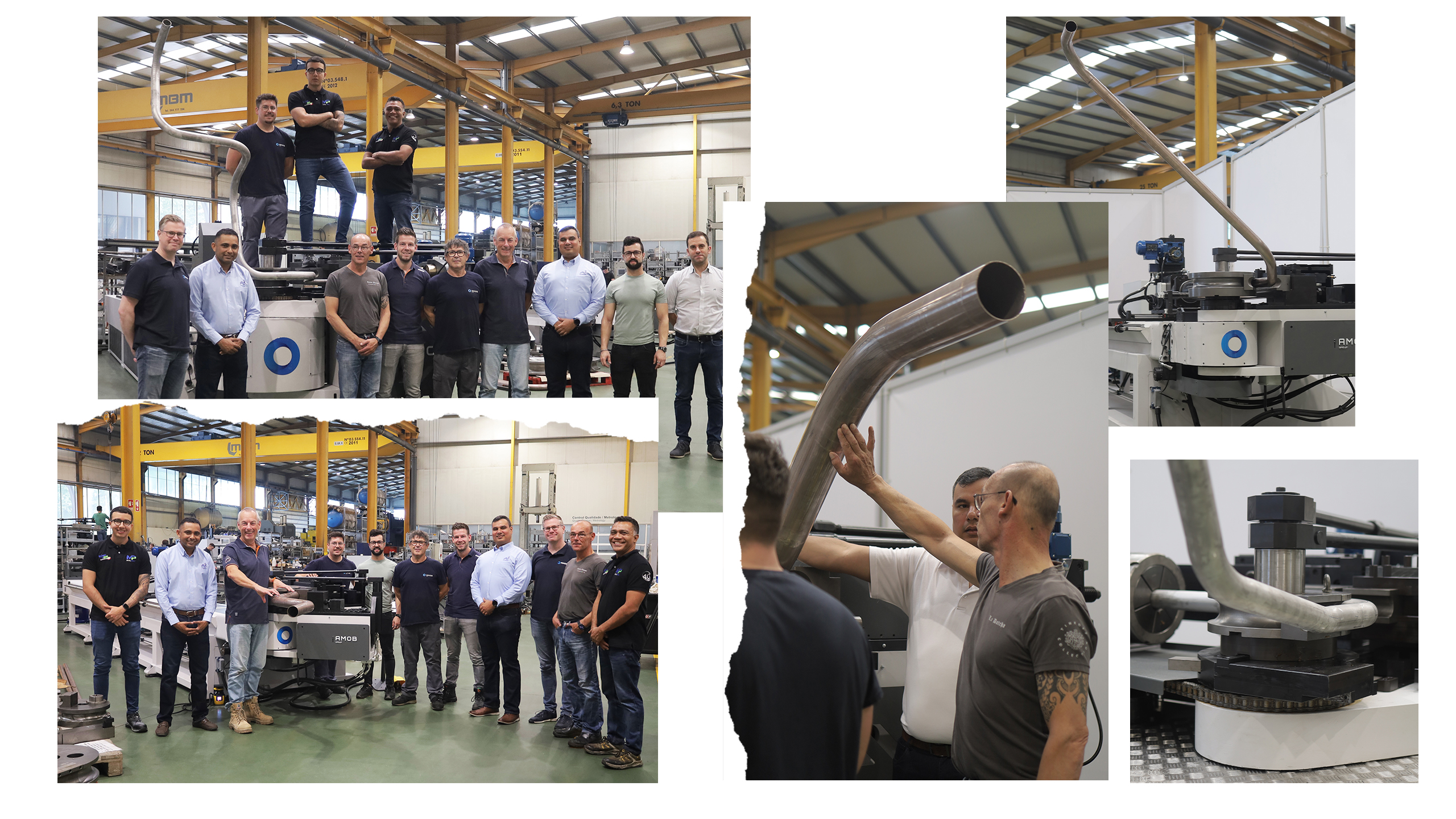

Just a few months after the contract was signed, the machines underwent successfully through FAT (Factory Acceptance Test) carried out at AMOB’s facilities, confirming that all technical and quality requirements were met.

The success of this project marks an important step in the evolution of the partnership between AMOB and Damen Naval. During their visit to AMOB’s facilities, Damen representatives had the opportunity to see not only the full range of machines but also the entire infrastructure that supports the company’s operations. They were impressed not only by the efficiency, precision and versatility of the technology presented, but also by the fact that AMOB develops and produces everything in-house, ensuring full control over quality and the ability to respond immediately to any challenge.

With this project, AMOB strengthens its role as a strategic partner for leading companies in the sector, delivering solutions that combine innovation, technology and robustness for projects across the four corners of the world.