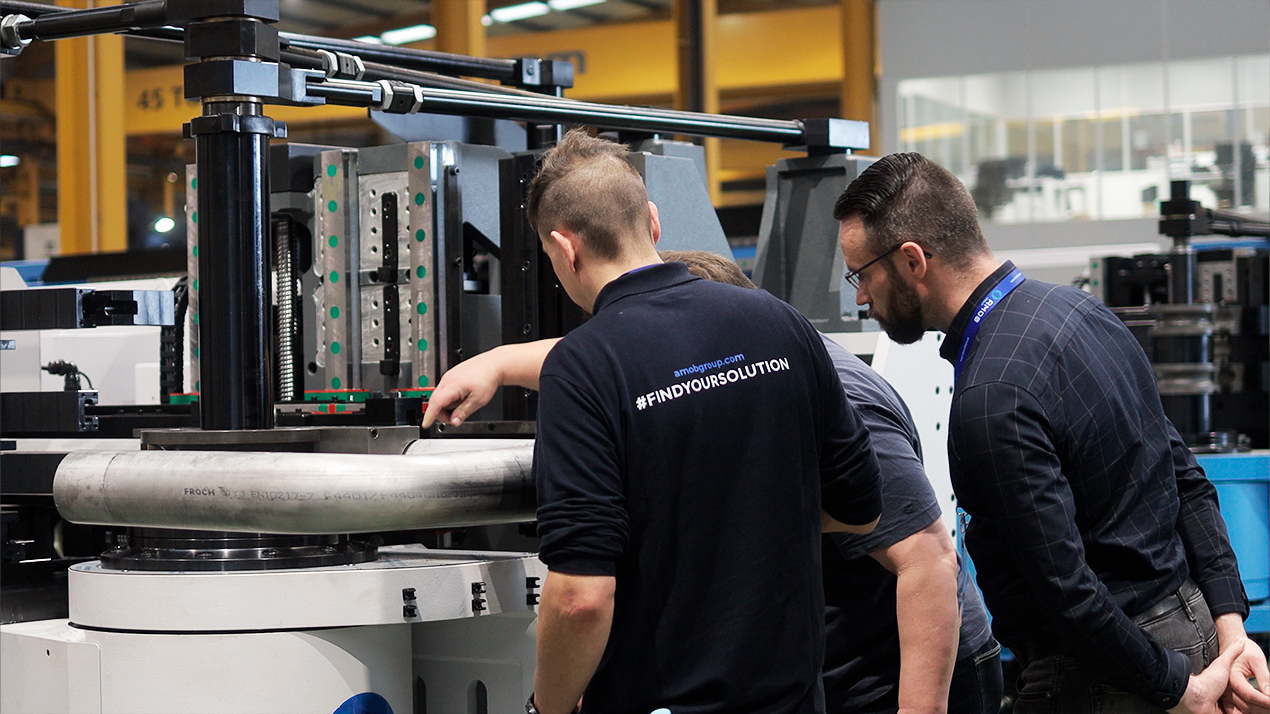

VIAFIN acquires the new eMOB 130

VIAFIN

VIAFIN is one of Finland’s leading industrial maintenance service companies. It has solid experience in the maintenance and upkeep of pipelines in the processing industry, as well as in the installation of pipelines and equipment at natural gas terminals. In the energy sector, VIAFIN is particularly involved in projects related to the production, distribution and refueling of natural gas. VIAFIN has 32 service units in 23 locations in Finland, which allows for a fast and efficient service. They are able to carry out projects according to their customers’ investment needs for new installations, but also for existing installations.

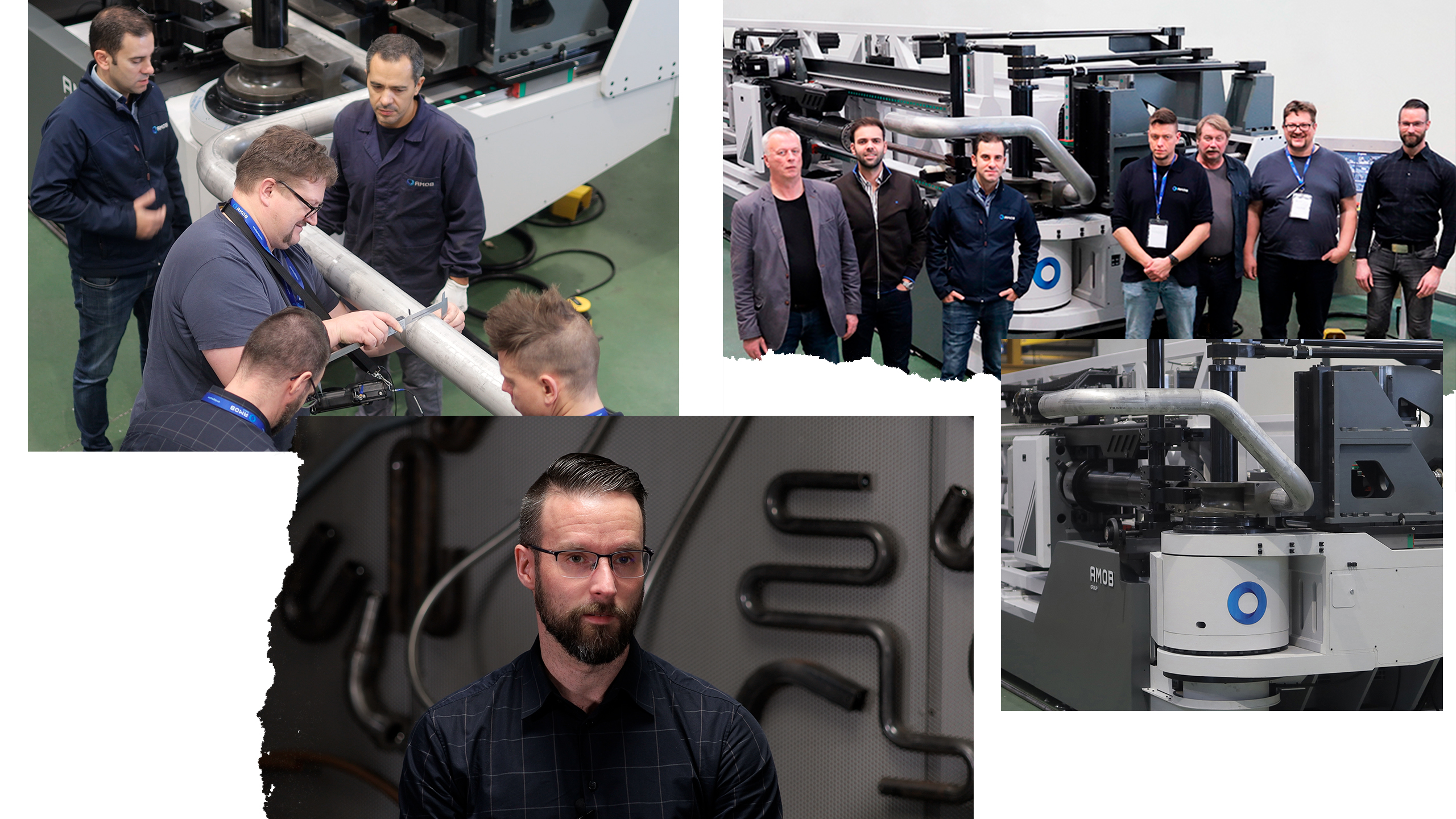

With remarkable growth in recent years, this company felt the need to strengthen its production system and acquired a 100% electric tube bending machine – eMOB 130. It’s a machine with a totally new concept, where the head is fixed and vertical and horizontal movements are performed by the carriage. With this upgrade, AMOB aimed to solve 2 critical requirements for all customers with this machine concept, which are: low loading height and improved tool stacking capacity (one of the biggest in the market on this regard).

In addition to these factors, the tangent booster optional of this machine helps with the pushing force into the bend when the positioner cannot go inside the bending tool area. This avoids a possible collision while maintaning a proper bending support helping to achieve precise and consistent bends.

This fully electric tube bending machine from the eMOB series features the latest bending technology, capable of processing tubes up to 130mm outside diameter. Can perform bends with fixed and variable radii within the same cycle, special sections, has multi-stack up to 8 tools at the same time and can perform bend-on-bend parts. High-quality results with minimum ovality even on smaller radius-to-diameter ratios.

With AMOB 3D Software it’s possible to visualize every machine detail and each component with a true 3D representation, simulate the bending cycle, identify any collision and have full control of your bending machine. The AMOB 3D software is the perfect symbiosis between user and hardware, maximizing the stream of information and control with a user-friendly interface.

VIAFIN‘s production system will undoubtedly be strengthened by the eMOB 130. This will make it possible to reduce production times and, consequently, delivery deadlines. The company also intends to expand its business to other countries.