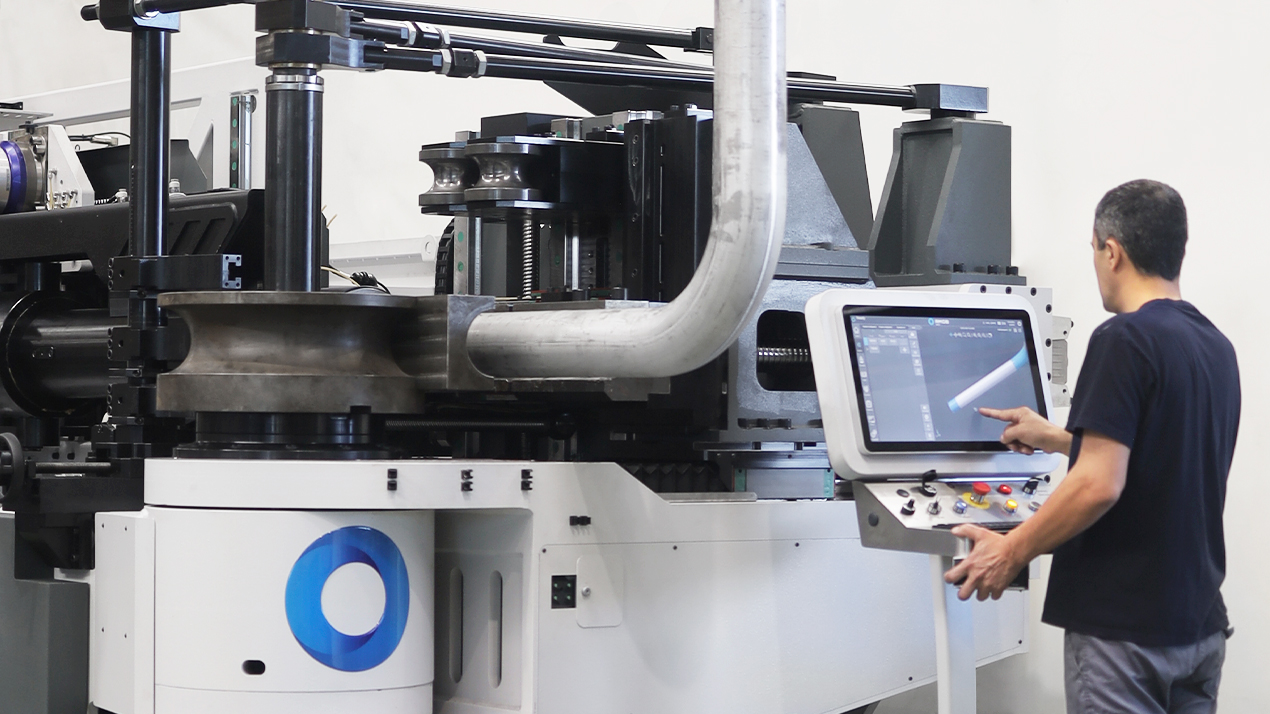

Discover the advantages of choosing a 100% electric tube bending machine

100% electric tube bending machine

In this article we find out about the main advantages of choosing a fully electric bending machine with the most intuitive software on the market.

1. Energy saving / Eco-Friendly: Due to its servo technology this machine is the most energy efficient machine available in the market. The electric servo motors have the highest rate of energy efficiency and only consume energy when needed. This fully-electric tube bender has superior no oil-fluid systems and will not leak or produce heat or noise, providing a friendly and pleasant working environment. Furthermore, all machine components are recyclable.

2. Safety and Working environment: Safety is a prime concern with a machine that moves as quickly and quietly as a fully electric bender. Our fully-electric machines are integrated with several safety features such as safety fence, area laser scanners, buttons for emergency stops, safety tooling set-up parameters,in-cycle pre-coded verification of bending operation, amongst others, making it CE compliant to guarantee safe working environment.

3. Speed and Reduced cycle times: Fully electric machines work at high speed with complete control. Each and every axis is independently controlled by absolute servo motors, meaning the speed and movement of each can be synchronised and optimised to perfection for example by linking different machine movements by combining 2 or more axes simultaneously, drastically reducing the cycle time compared to hydraulic machines.

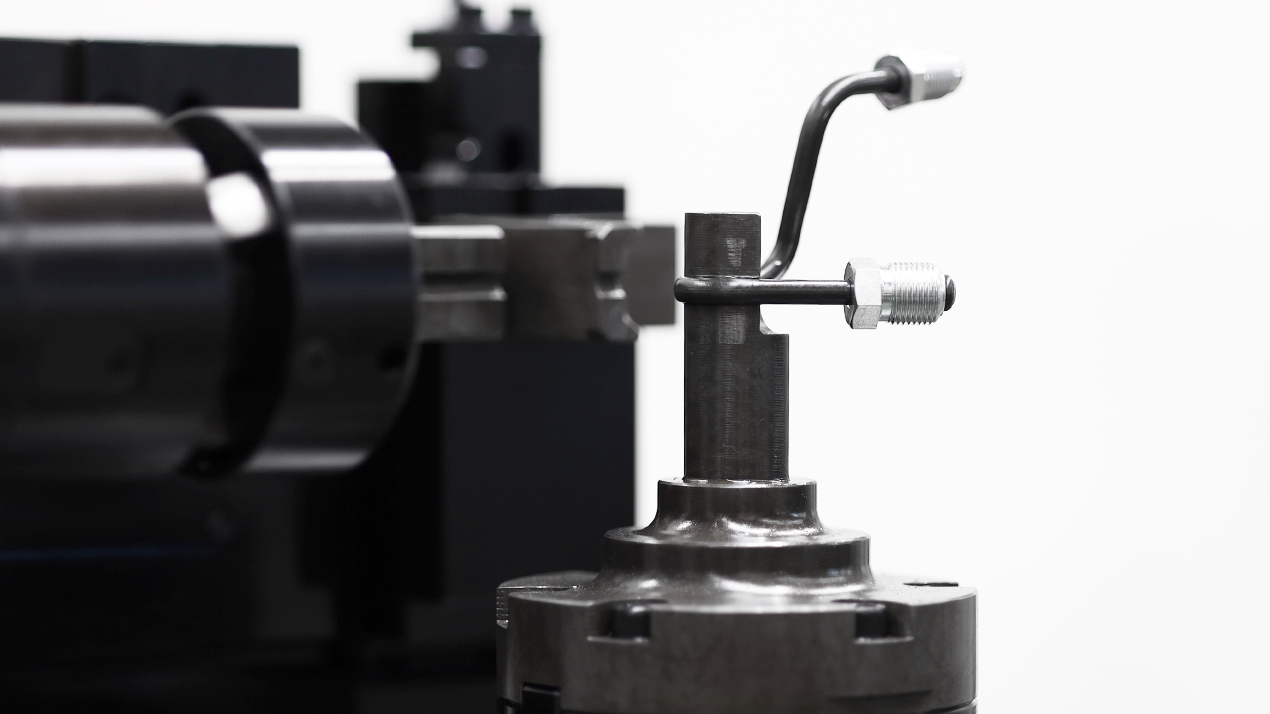

4. Accuracy/repeatability: The electronic motion control system of the motors assures that the chosen position will always be the same. Fully-electric machines are not subject to behaviour changes along the way, meaning there’s no time or material lost tweaking the machine unlike hydraulic benders. Electric machines store bending parameters which can be saved and reused every time a given part is produced.

5. Higher productivity: By selecting a servo electric machine your productivity is boosted no only by shorter cycle times, but also low setup between projects, no adjustments during production, no wasted parts, energy cost reductions and low maintenance procedures.