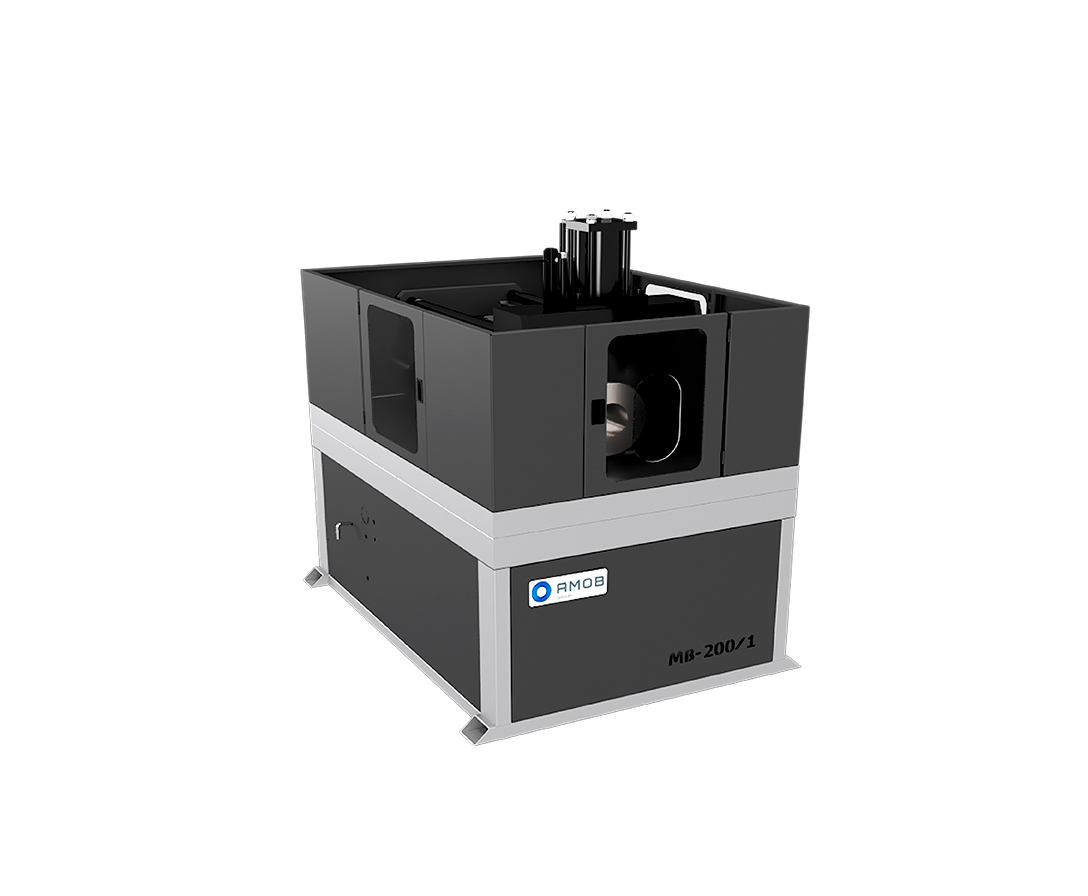

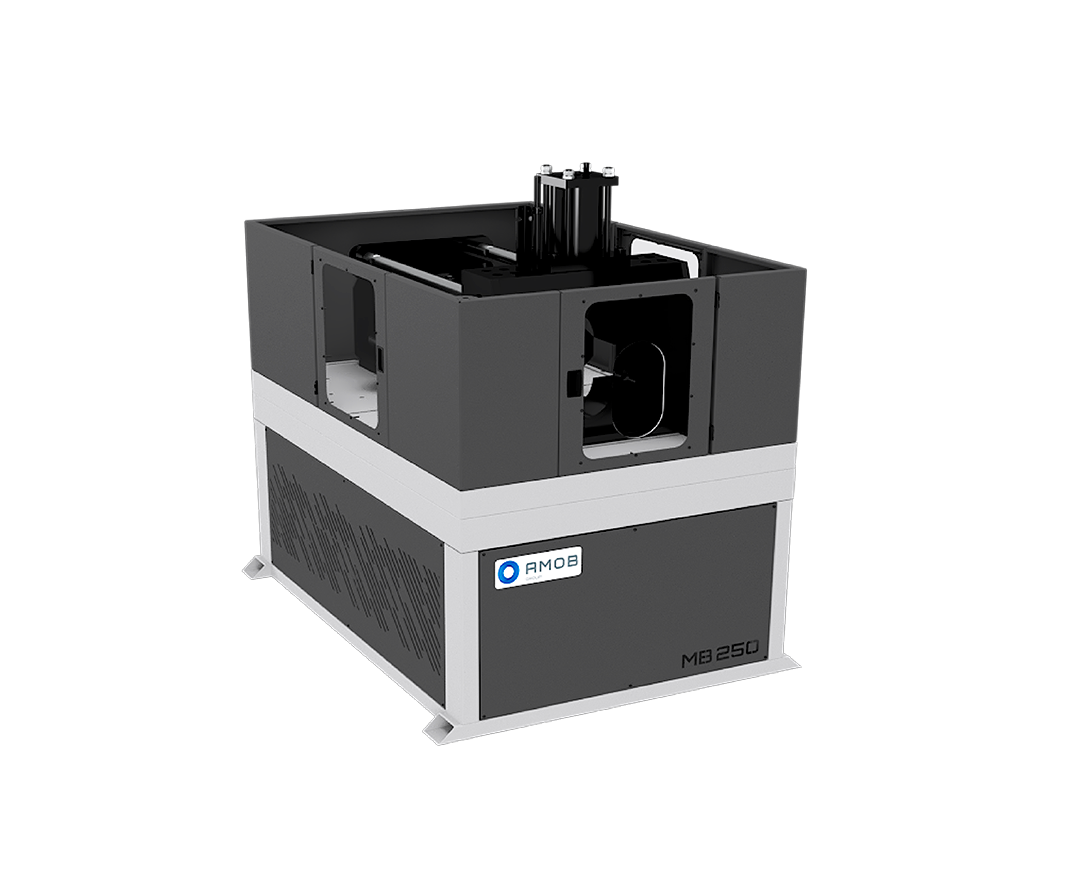

Tube End Forming Machines –

MB Series

TUBE END FORMING MACHINES

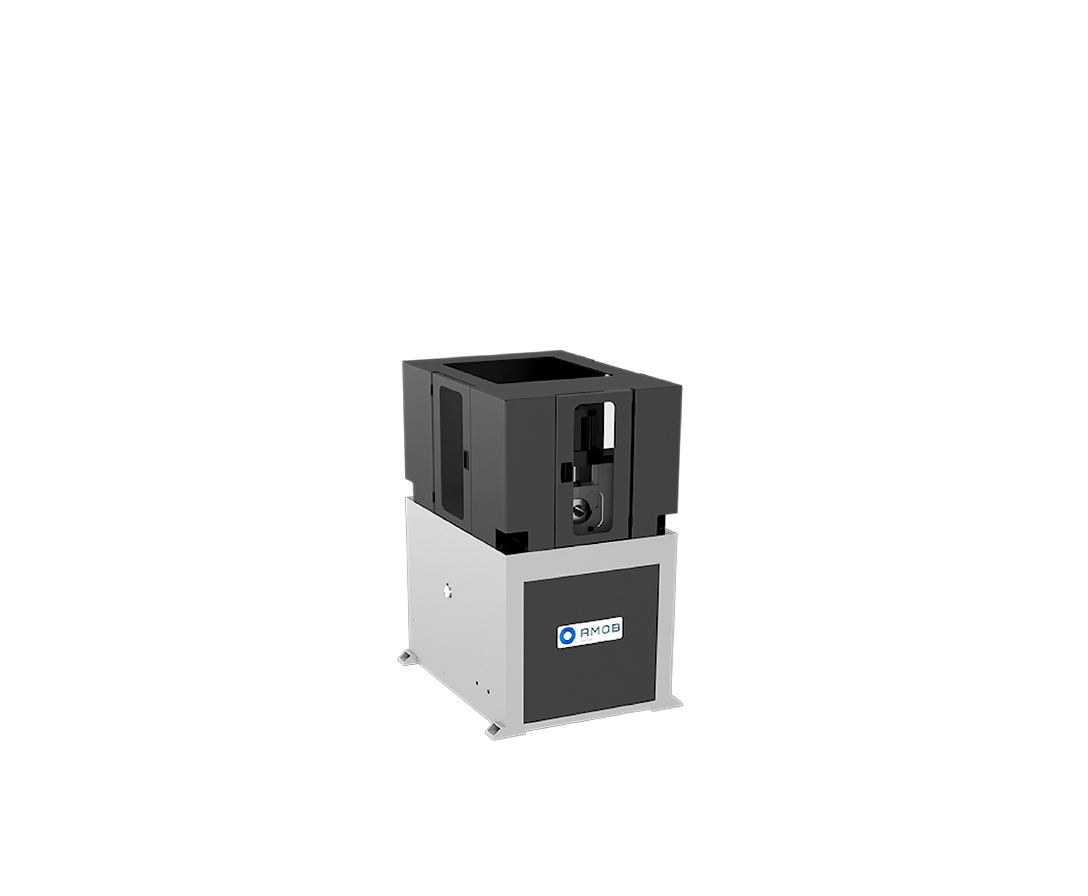

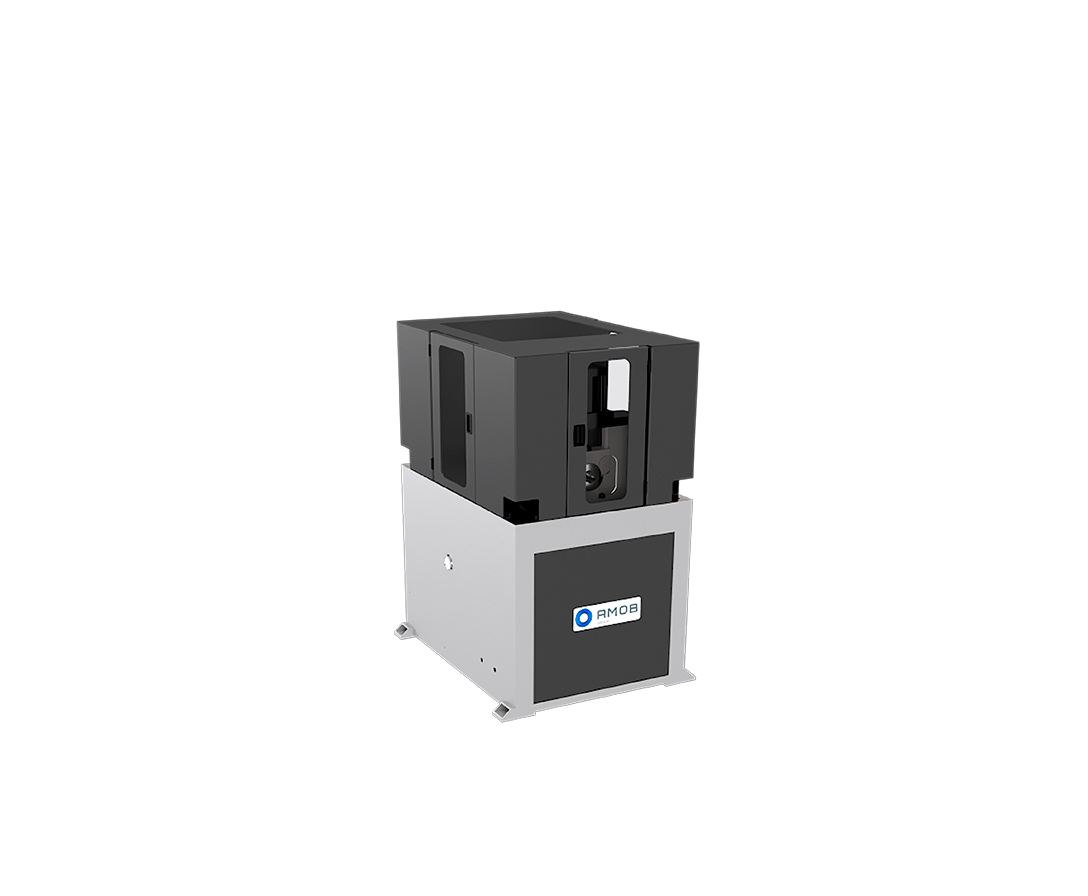

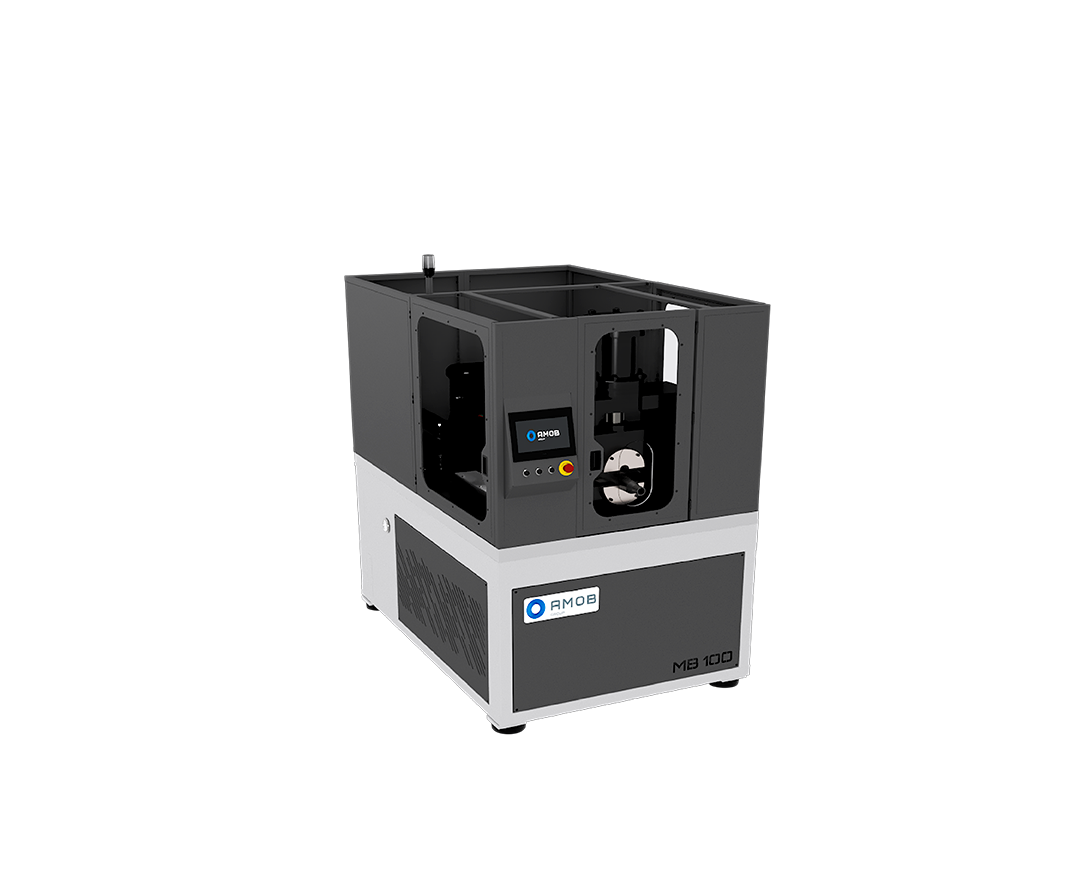

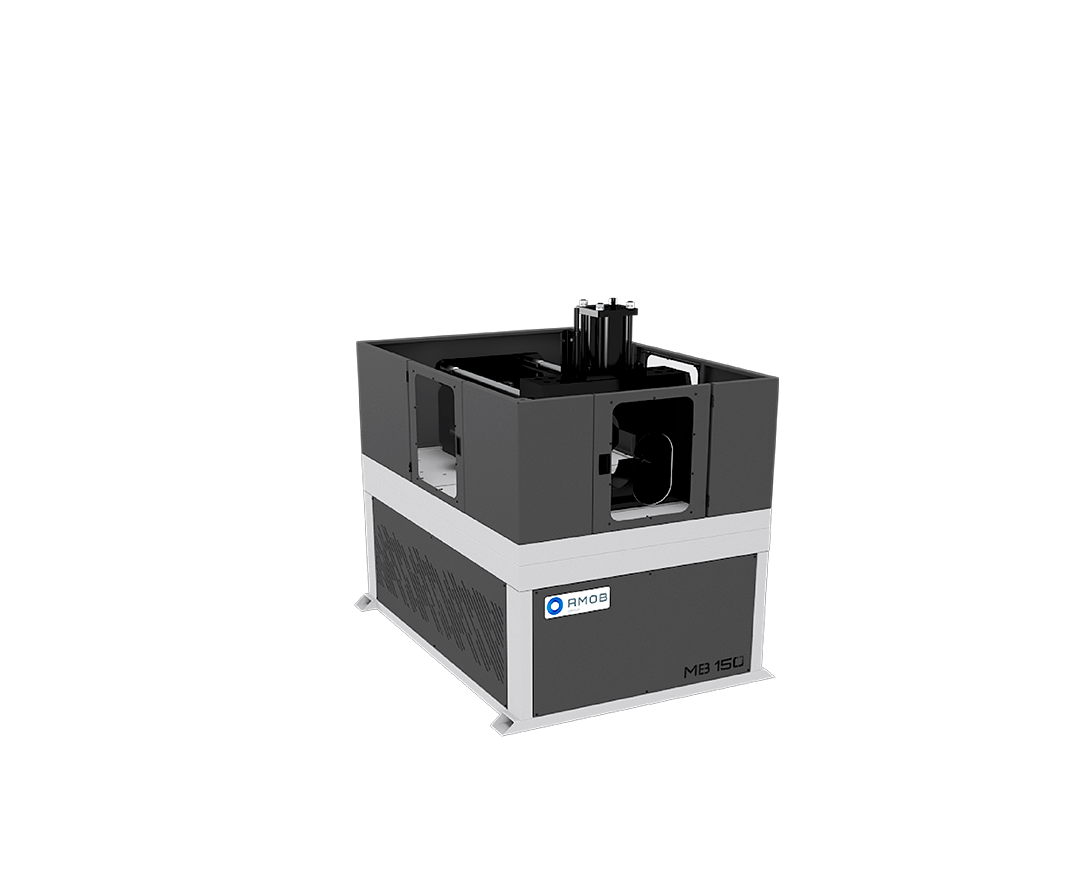

We can divide the MB series into 3 main subcategories: MB/1 with only 1 forming station, MB/2 with 2 forming stations and finally, MB/D which has 1 or 2 forming stations on each side.

MB/1 and MB/2 With a user-friendly touch screen, these tube end forming machines with 1 or 2 stations are driven by servo controlled axes and allow the creation of programs to use their available stations. These machines exhibit a more rigid construction ensuring precision and repeatability. The ideal solution for the simplest applications.

MB/D The main feature of this model is the simultaneous end forming on both ends of the tube. This is only possible due to the existence of forming stations placed on each side of the tube. Driven by servo-controlled axes, MB D makes it possible to adjust the distance between stations according to the tube length. It also has a touch screen with storage of positions and programs.

FEATURES TO TAKE YOU TO THE NEXT LEVEL

The MB series has a user-friendly touch screen with the ability to store positions and programs.

Excellent results in any application because of AMOB’s design capability and production methods.

These versatile machines with high portability and small footprint are great for smaller workspaces.

High repeatability and reduced material waste. The final product is ready to ship in a few seconds.