Verticality of the production process

The new controller

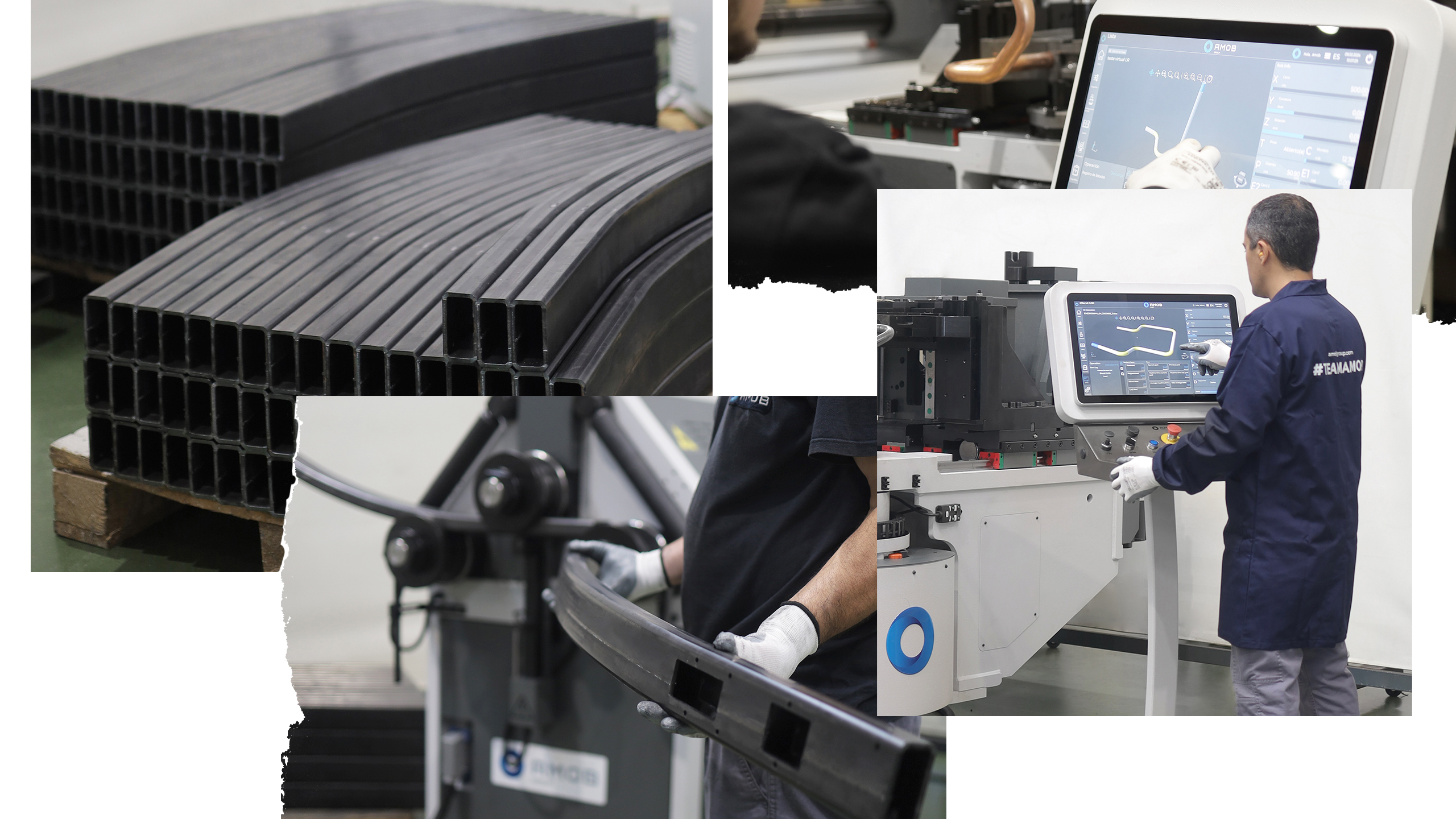

AMOB continues to demonstrate its commitment to innovation and quality by manufacturing the structure of its own controller using AMOB machines. This achievement underlines the company’s ability to control the entire production process, from design to product completion.

By using its own machines to manufacture important components such as the controller, AMOB guarantees maximum precision and reliability while maintaining high quality standards. This approach not only reinforces the company’s self-sufficiency, but also exemplifies the effectiveness and versatility of AMOB‘s solutions.

This closed production cycle is proof of AMOB‘s confidence in its own technologies and an additional guarantee for customers that every detail of its products is carefully controlled and produced to the highest quality.

The controller structure holds the software for AMOB machines, a fundamental piece that links AMOB hardware and software, ensuring that the robustness and precision of mechanical components of our machinery are complemented by efficient control of the operating process. Below is a summary of the features and functionalities of AMOB 3D Software:

AMOB Software Features

1. Intuitive interface: The software is designed to be “user-friendly” with a clear and easy-to-use graphical interface. This allows less skilled operators to intuitively and easily learn how to use the machines efficiently.

2. Advanced programming: Offers advanced programming possibilities, allowing complex bending programs to be created, edited and stored. Programming can be done directly on the machine or via remote connection, allowing for greater flexibility, ergonomics and operator well-being.

3. Precision and repeatability: The AMOB 3D software controls the machine‘s movements with the highest precision, ensuring that all bends are made according to the exact design specifications. This results in high repeatability and consistency of all parts produced.

4. Simulation and verification: Includes simulation tools that allow us to check and adjust the bending programs before starting production. In this way, we can identify and correct possible errors and avoid wasting time and materials.

5. Integration with CAD: It is compatible with CAD systems, allowing direct import of technical drawings, which facilitates the transition from design to production.

6. Monitoring and reporting: Provides real-time monitoring functionalities, as well as, detailed reporting on machine performance and production activity contributing to the optimization of the production process.

7. Updates and technical support: AMOB offers regular software updates, ensuring that customers have access to the latest improvements and features. In addition, the company provides specialized technical support to resolve any problems that may arise.

AMOB’s software solutions allow machines to be adapted to a wide variety of sector-specific requirements. This software is a crucial component that maximizes efficiency, precision and flexibility in the bending of tubes and profiles.